5 Kilogram (MOQ)

| Business Type | Exporter, Supplier, Trader, Importer |

| Wire Material | Inconel |

| Shape | Round |

| Color | Grey |

| Click to view more | |

Product Details

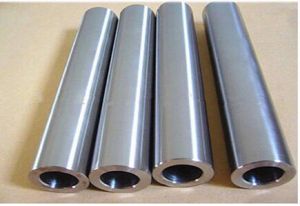

Sankalp Alloys Overseas supplies a fantastic of Inconel 718 Wires to its clients all over the planet. We even item these wires in various specifics, rules, thickness, estimations, lengths, sizes, and shapes. We furthermore fulfill the custom necessities of clients as indicated by their application's requirements.

Inconel 718 Wires are a phenomenal thing that is useful in various applications. The wires are made of Inconel 718 mixture by virtue of its various characteristics. This is a mix of nickel, chromium, and molybdenum. The mix was at first developed to go against disastrous circumstances. Additionally, it was made for restricting conditions like gap and pitting utilization as well. Beside this, the Alloy is said to have a couple of exceptional properties, for instance, creep break, high versatility, and exceptional yield strength. These properties are appealing at high working temperatures.

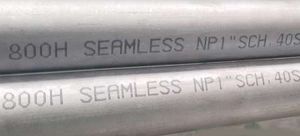

ASTM B166 Inconel 718 Wire, Alloy 718 Wires, Inconel N07718 Wires, Inconel Alloy 2.4668 Wires, Inconel 718 Wires, Nickel Alloy 718 Wire, 718 Inconel Wire, Inconel 718 Wires Suppliers In Mumbai, India

Thus, our Inconel 718 Wires can be used at 1200 degree F temperature that is cryogenic temperature. Inconel 718 moreover contains niobium which adds an original property to it. In this way, age hardenable is basic where unconstrained cementing isn't required while warming and cooling the blend. In like manner, the Alloye can be hardened and weld easily. The blend of niobium and molybdenum adds fortitude to the mixture by which heat treatment isn't needed. The blend can be easily produced in conditions like precipitation or hardening. The identical is legitimate for welding moreover. This huge number of designs make it a superalloy.

Likewise, the things made of Inconel 718 are worthwhile in substance dealing with, tainting control gear, marine planning, nuclear reactors, avionics, and various undertakings. We serve Inconel 718 Wires to these endeavors. Our things have characteristics like high impact strength, pliable, chloride safe, and anything is possible from that point. it can go against SCC at a temperature extent of 982 to 1800 degree F. it thoroughly hinders attack by chlorides, sulfides, carbon dioxide, and pitting in undermining conditions.

Anyway, imperative tests ensure that they are sensible under such threatening circumstances. Thusly, we play out especially critical tests proposed under worldwide standards. These are hardness, impact check, positive material distinctive confirmation, moldable, smaller than expected, full scale, intergranular utilization test, ejecting, evening out test, from that point, anything is possible. Tests as well as a fundamental piece of Sankalp Alloys Overseas.

Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 718 | 2.47 | N07718 | NCF 718 | - | - | - | - |

Chemical Properties

| Grade | C | Mn | Si | Cu | S | Cr | Fe | Ni | Co |

| Inconel Alloy 718 | 0.08 max | 0.35 max | 0.35 max | 0.3 max | 0.015 max | 17 – 21 | 6.00 – 10.00 | 50 – 55 | 1.0 max |

Mechanical Properties

| ensity | Melting Point | Tensile Strength | Yield Strength 0.2% Proof | Elongation (% in 50mm) (thick.>0.76mm) |

| 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 135,000 , MPa – 930 | Psi – 70,000 , MPa – 482 | 45.00% |

Looking for "Inconel 718 Wire" ?

Explore More Products